|

|

Post by BERNARD "HOT ROD" KRON on Apr 14, 2012 14:25:58 GMT -4

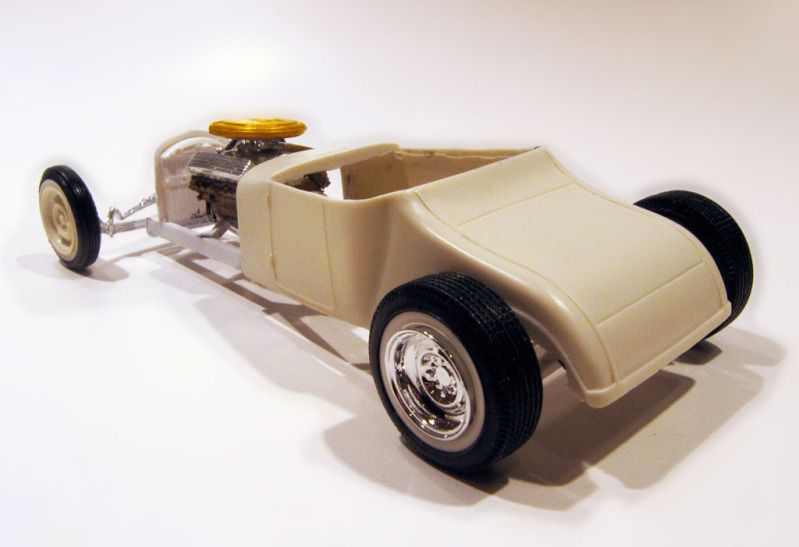

Mockup for stance check, held together by rubber cement... The front and rear suspension are finalized - Revell '29 Ford RPU all around with an AMT '34 Ford rear spring. I'll show the chassis when it's cleaned up a bit more. The rear wheels are the ones I'll be using (from Modelhaus). The fronts will be chrome ones like the ones you see. The tires will be either these or slightly wider ones. Alternate tires and the chrome front wheels are on order from Modelhaus so that will probably be the long pole in the tent... Chopped Revell Deuce grill shell. I'm pretty sure I'll be running lakes pipes under the body to add some interest to the lower edge of the car. I'll probably have to make them. The really big challenge is now, and has always been, scratching together an interior. Probably no way to avoid it any longer... Thanx for lookin', B.     |

|

|

|

Post by KRAZY RICK on Apr 14, 2012 19:11:43 GMT -4

That profile is perfect !! ....Really Super   |

|

|

|

Post by BERNARD "HOT ROD" KRON on Apr 14, 2012 19:45:58 GMT -4

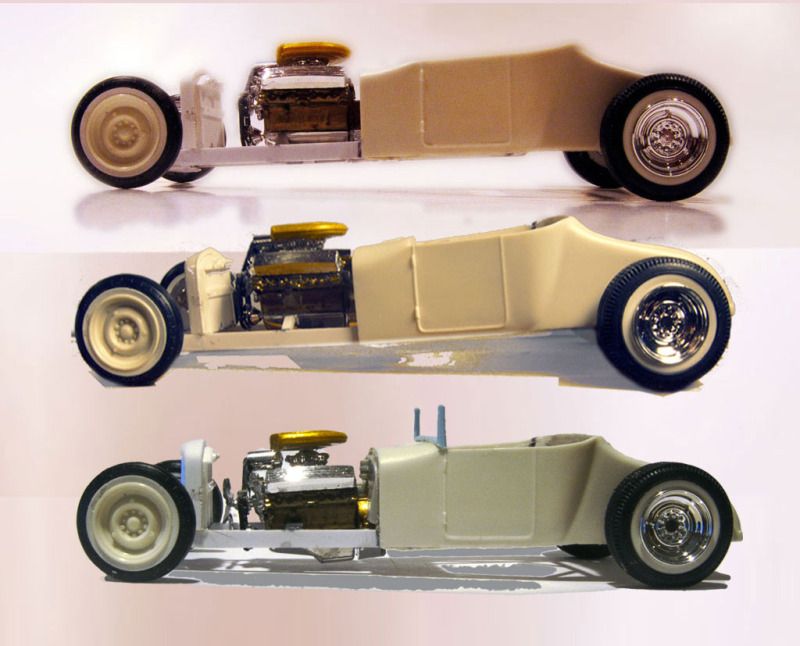

Thanx Rick. I do these mockups and stance checks at the beginning to make sure things look right and will go together properly. Looking at the car in photos and also "in the plastic", there was something that bothered me. It looked a little stretched out. I decided it was because the rear wheels were a little too far out at the corners, so I moved the rear axle in about 1/8 inch or roughly 3 1/8 scale inches. This tucks the top of the rear tire below the trunk line creating a symmetry between them, and makes the car slightly more close coupled without spoiling the Lo-Boy effect. Belows is a comparison between the two with new stance at the bottom. The camera angle isn't a perfect match but I think it shows the difference.  |

|

|

|

Post by BERNARD "HOT ROD" KRON on Apr 17, 2012 17:38:12 GMT -4

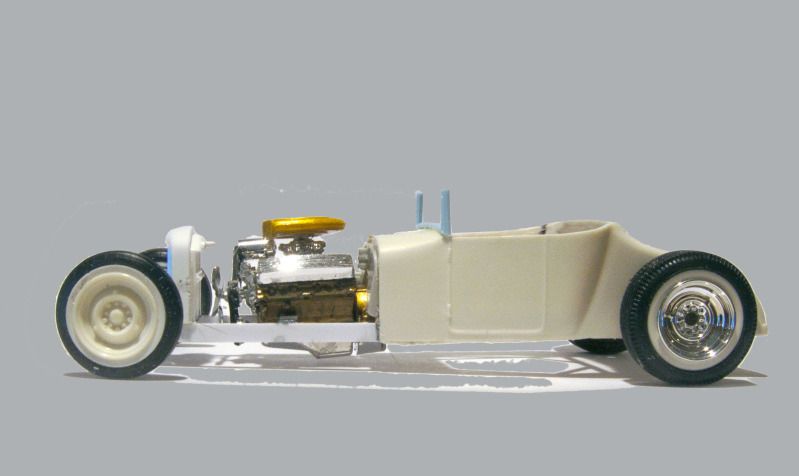

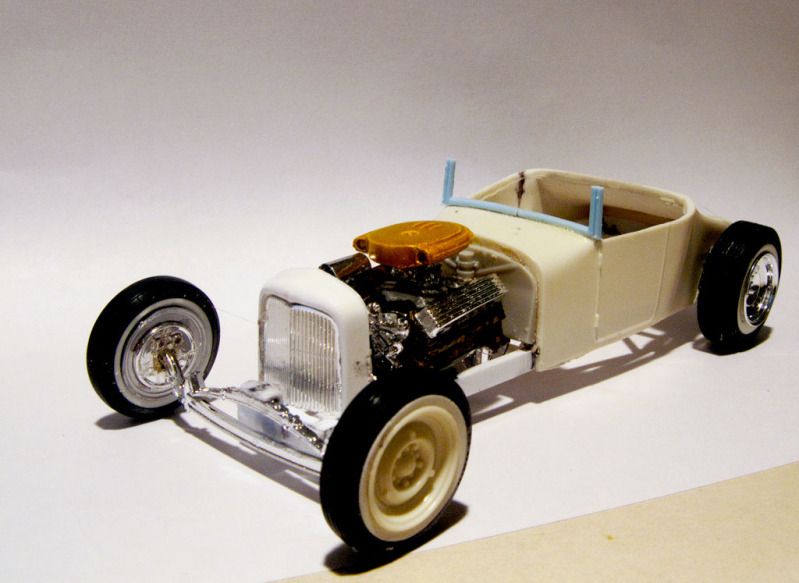

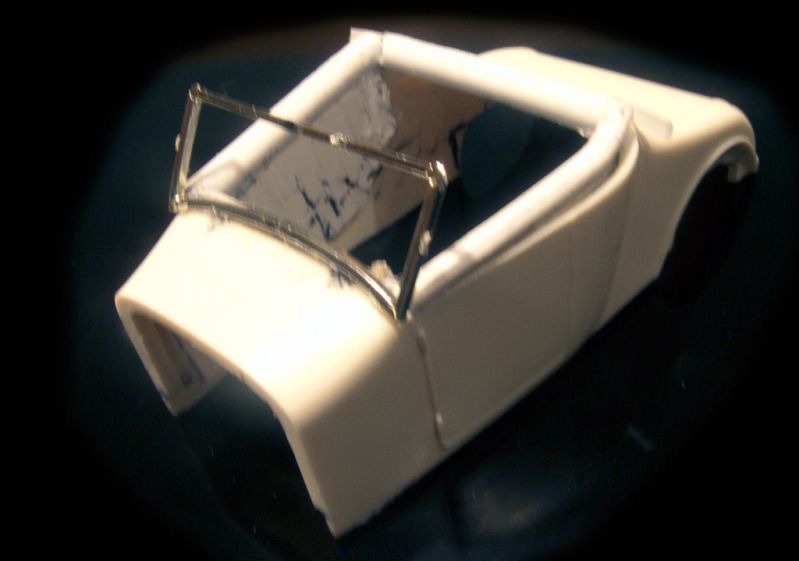

I’ve received several comments regarding the stance of this car and decided to revisit it one more time to dial things in to address what I thought were some perceptive and constructive observations. The result was that I did an extensive re-do of several areas. To begin with, I noticed that the rear axle interfered with the lower edge of the body, causing the body shell to be jacked up and spoiling the original channel I had done. Removing some additional bodywork to clear the rear axle corrected this problem. Next up was that I noticed that the front end was extremely low, creating a more extreme rake than I wanted and causing the front end to look more stretched out than was desirable. By lowering the suicide perch I raised the front end about 1/16” or about 1.5 scale inches. Lastly, the motor sat too high relative to the bodywork, a problem made even worse once I corrected the rear axle interference. I made several changes to address this, the goal being to place the upper edge of the oil pan at the same level as the tops of the frame rails.. First of all I changed the transmission from the very large automatic transmission that comes with the Parts Pack Cadillac to a compact little La Salle box which lowered the back end of the motor without having to rebuild the center crossmember. Next I fabricated new engine mounts that were slightly narrower and extended horizontally from the frame rails to support the engine at the center of the block casting rather than at the lower edge of the crankcase. With the engine lowered relative to the cowl top I found it necessary to raise the air cleaner slightly so I fabricated a small spacer placed between the air cleaner and the carburetor. With all these changes it was necessary to finalize the motor location in order to dial in the grill shell placement, a design element which is critical to determining if the front end would appear too stretched out. This required fabricating the firewall, which I made from an AMT ’29 Ford roadster unit. In addition I installed the motor’s chromed fan. And finally, because it effects where the eye is drawn in evaluating the overall stance, I mocked up a windshield frame resembling the unit on the Anderegg car. One more change still needs to be made. With the body properly located now, the grill shell will need to be cut down some more to align properly with the cowl. All this work really has made a big difference. The car sits more solidly on its wheels and looks more put together than it did. So , thanks to those who were interested enough to comment. Thanx for lookin’ B.     |

|

|

|

Post by KRAZY RICK on Apr 17, 2012 21:16:25 GMT -4

That was definitely well worth the effort, the stance & look are very balanced; what a perfect example of a true Hot Rod   |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 18, 2012 6:32:37 GMT -4

Bernard,,,They all look good to me!!!!,,,where is the air breathre from ???I have been looking to see what kit it comes in,,i have a stalled project waiting for it. ;D

|

|

|

|

Post by BERNARD "HOT ROD" KRON on Apr 18, 2012 9:28:16 GMT -4

...where is the air breathre from ???I have been looking to see what kit it comes in,,i have a stalled project waiting for it. ;D It's from Modelhaus, 1953 (53-56) Cadillac air cleaner found under Parts - Customizing Parts on page 1. available either in plain resin or chromed: www.modelhaus.com/index.php?y=&c=&pt=18&part=1&Submit=Search |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 18, 2012 17:42:00 GMT -4

THANK YOU!!! ;D  |

|

|

|

Post by BERNARD "HOT ROD" KRON on Apr 20, 2012 5:34:10 GMT -4

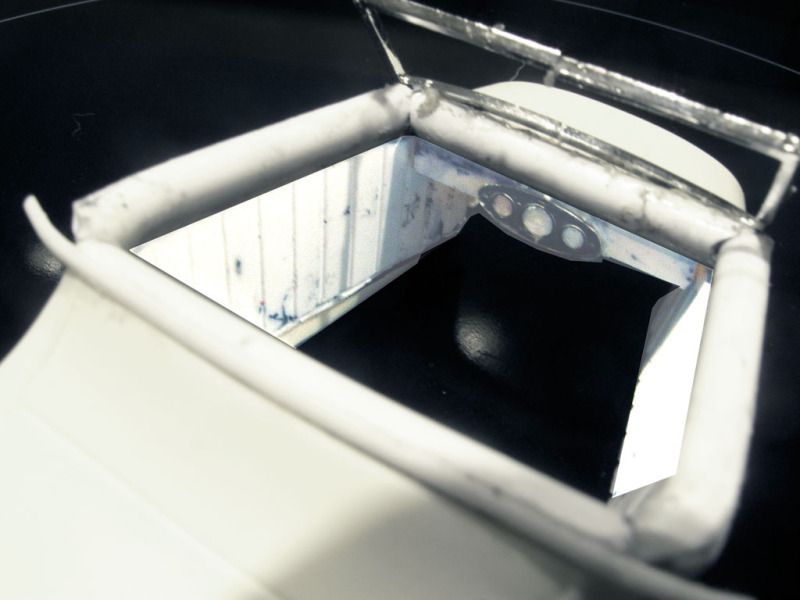

I’ve made a small modification to the engine mounts so that the motor now sits with the valve covers parallel with the frame rails and the top of the oil pan just about even with the top of the frame. This update is Part One of the interior fabrication. One of the challenges one faces when working from a resin body for which there is no equivalent kit is that a large part of the build must be made from scratch. I find the process is often part logic and tactics and part accident and discovery. This is an excellent example of what I mean. To start with I made an interior structure by tracing a pattern directly from the inside surfaces of the body to paper. Then I copied the pattern to a sheet of .010” styrene and cut it out. This would form the base for the actual surfaces you would see. Here is the pattern displayed flat and then installed in the body. It’s held in place using rubber cement.   Then I fabricated the “upholstered” surfaces using Evergreen Novelty sheet styrene in a siding pattern for the main surfaces and styrene half-round rod to make the bolster that will run around the outer edge of the body. The bolster was built up from .1875” stock and .080” stock glued together to form a “P” shape. The pieces were based on the original pattern I made and trial fit and trimmed using rubber cement before being permanently glued to the base using liquid cement. Here are the pieces that resulted. As you can see the base has broken apart from handling. The .010” styrene sheet becomes quite brittle and fractures and tears easily. However, I didn’t want to use anything thicker to minimize fitment issues. (The photo is out of sequence as will be explained below.)  Once the upholstered surfaces were finalized and glued in place to the base I clamped them in place and left them for a time in order for the plastic to gain some memory and conform to the compound curves of the interior. That explains the curved ends in the photo above. I discovered that once the interior tore apart installation of the interior pieces became much easier with no sacrifice of accuracy of fit.  And finally, here is the completed interior as it stands up to this point. You’ll note the small half-round .080” strips sticking out on the ends at the back. These will be bent home and glue in place to form a continuous strip and the seams and gaps filled and sanded to final shapes. Tactically this means the interior will have to be glued into the body before painting and the body masked and the interior painted but I can’t think of a way to avoid this.   It should be obvious that my build style is pretty improvisational, with some advanced planning but a lot of “on the fly engineering”. I haven’t decided whether to make a bench seat or use buckets. The inspiration cars both have bench seats. I’ll probably try both before deciding. A floor needs to be fabricated and a dashboard made. About the only thing I’ve decided on in advance is to use a ’60 Chevy Impala steering wheel from Modelhaus which will influence my design decisions. Thanx for lookin’, B. |

|

|

|

Post by KRAZY RICK on Apr 20, 2012 7:53:30 GMT -4

That's alot of scratch building Bernard, I can't wait to see that interior in paint   |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 20, 2012 9:21:19 GMT -4

really lookin good guys !

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 20, 2012 18:45:13 GMT -4

Looking GOOD so far , Bernard. Make sure to keep us posted as you progress..

8-)RICK

|

|

|

|

Post by BERNARD "HOT ROD" KRON on Apr 25, 2012 17:01:56 GMT -4

Thanx guys! This is a small update which actually represents a fair amount of work. The body is narrow enough that using bucket seats proved impractical. In order to build out a bench seat I needed to finalize the floor of the car, The floor, in turn, needed to take into account the transmission and drive train to the degree to which it intruded into the cab. In a car this small everything is tightly interrelated. The floor was fabricated from styrene sheet, rod, and strip with a low transmission tunnel which doubles as a support for the bench seat. The “upholstery” for the seat bottom was made from the same half round rod and siding patterned styrene sheet as the sides and back. Below is a composite picture showing the interior and floor from various angles. It’s all in raw plastic because I’m trying to avoid gluing and painting until everything is fabricated and fully test fitted. This might sound obvious but in the past I have tended to glue and paint as I went along, leading to more problems than was necessary if I had been disciplined enough to complete all my sub-assemblies before doing finish work and assembly. Next up will be the dashboard and windshield, which, once again, are interrelated. Once that’s done the interior will be complete and I can move on to finalizing the suspension bits and beginning paint and assembly. Thanx for lookin’, B.  |

|

|

|

Post by KRAZY RICK on Apr 25, 2012 17:06:25 GMT -4

Wow !! ..... the interior looks really good ( as well as correct )  |

|

|

|

Post by BERNARD "HOT ROD" KRON on Apr 26, 2012 18:24:13 GMT -4

Thanx Rick! This stage of doing the interior is now complete. I made the dashboard and windshield, both of which will receive more work as the build progresses. I’m accustomed to making complete interiors in advance of final assembly, including all paint and finish work. But that’s not possible here because of the bolster which runs all the way around the interior. It needs to be glued into the body before final sanding and filling to shape. After everything is primered using white primer I’ll mask the body and finish out the interior in Testors Pearl White. Then I’ll mask the interior, remove the body masking and paint the body Testors Inca Gold. The dashboard turned out to be a very simple affair, with the continuation of the bolster across the front of the cabin and a simple rectangular dash with an oval extension dropping slightly below the lower edge containing a Model Car Garage photo-etch instrument cluster. The windshield is a narrowed AMT ’32 Ford Phaeton piece which is held in place currently with rubber cement. It will most likely be chopped and have the upper cross piece removed. For now it’s onwards to chassis, suspension, and body finish work in preparation for paint. Here are a coupla pics. Thanx for lookin’, B.   |

|

|

|

Post by MOPAR KEN on Apr 26, 2012 23:07:13 GMT -4

This is looking great. The new stance is perfect

|

|

|

|

Post by BERNARD "HOT ROD" KRON on May 17, 2012 14:38:53 GMT -4

Giant sigh of relief!!! I got the basic painting done, but not without some heavy melodrama. I started by shooting the frame and body in Duplicolor white primer. Then I masked the main body surfaces, leaving the upholstery exposed. The interior colors (Duplicolor Ivory White covered with Testors White Lightning pearl white) went on OK. Then I removed the main body masking and masked the upholstery surfaces in preparation for shooting the main body color of Testors Inca Gold. So far so good... Unfortunately I got a defective can of Inca Gold which spattered as I sprayed the first coat. The damage was done, setting the basis for a bad case of orange peel. So I shot more color to fill in the gaps in the spatter. Then I waited 10 days for the paint to get good and hard and wet sanded with 1500 grit and 2000 grit and polished out the result. The paint surface was now nice and smooth but the uniformity of the metallic pattern was gone and there were spots where the primer showed through. So I got a replacement can of Inca Gold and hoped it was a good one. This time I test shot it on some scrap bodywork. It was good! And it went down smooth on the body!!! Then I applied 4 coats of Duplicolor clear. The moment of truth came with removing the masking which, it turns out, will require no touch up and has nice crisp edges. Here's a color check picture taken in bright sunlight. The contrast between the white upholstery surfaces and the flaked gold paint is what I was after. Major relief on my part... I'll wait a few days to polish out the clear. Meanwhile I'll paint the grill shell and some frame bits and begin assembly work.  |

|

|

|

Post by KRAZY RICK on May 17, 2012 23:50:43 GMT -4

That looks damned good Bernard, But .... With all the care & work you put into these; You really should consider an airbrush; you'll have 100% control & be able to have the freedom of any & all color choice - with the cans ... your at the mercy of luck & have limited color options

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 18, 2012 22:58:13 GMT -4

looking good Bernard

l would have to agree with rick after l painted the the big "T" l had trouble as well and went to my airbrush

with l haven't used it about 6 years

and haven't looked back

more color choice and much more control

|

|

|

|

Post by BERNARD "HOT ROD" KRON on May 28, 2012 16:53:42 GMT -4

Thanx guys. I actually have an airbrush and even a decent compressor, but I haven't been able to find a place for a spray booth. I recently saw a how-to video on paint masking on another board where the guy doing it was using an airbrush and he was shooting in the open air in his hobby room and it didn't seem to concern him. Is a paint booth really necessary? Anyway... I continue to make progress on the Rumble Rod, although I'm moving pretty slowly because almost everything needs to be tweaked, modified, or built from scratch. The fact that I want lots of chrome means that hunting through my parts stash for the proper bits is especially demanding, since much of what I'm looking for has to be plated. Here are pictures of the completed chassis. The bulk of the suspension parts are from the Revellogram '30 Ford Sedan kit with the front shocks from an AMT '25 T and the rear shocks from an AMT '29 T kit (the hot rod parts). The AMT '34 rear spring has been foiled. I decided against the posable steering feature of the '30 Ford because I had to move the tie rod in front of the front axle and the whole affair was getting too fragile and fiddly. Also in the pics are the chrome front wheels from Modelhaus. The chassis will get a chrome drive shaft cut to length during final assembly, along with the steering box and shaft. I'm at the point where I can start final assembly and selection of the remaining detail parts such as the gear shift level, headlights and taillights. The most difficult part remaining will most likely be the fabrication of a pair of lakes pipes. Thanx for lookin', B.     |

|